PRODUCT

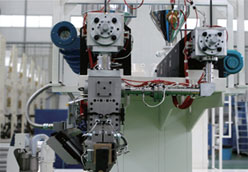

Extrusion Laminating Machine

Model : SWEL-250/SWEL-300

|

▣ Machine Advantages

|

|

|

|---|---|---|

|

Extruder and Dies High Output and good melting condition Even coating thickness and easy to control edge bead Automatic Profile control Motorized 3-way carriage movement | Screw and Barrel Computer modeled barrier screw Application for various resins Bimetalic hard Lining |

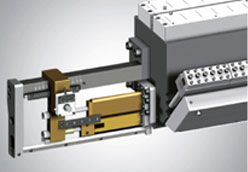

T-Dies Inner Deckle design Uniformity of coating thickness Easy to control edge bead |

▣ Specification

| Desription | SWEL-200 | SWEL-250 | |

|---|---|---|---|

| Machine Speed | 200mpm | 250mpm | |

| Web width | 1200mm | ||

| Kind of web | Plastic films, paper, Al-foil | ||

| Resin | LLDPE, LDPE, PP, EVA, EAA, Ionomer, Surlyn | ||

| Winding Diameter | ∮ 800mm, ∮600mm, ∮800mm | ∮800mm, ∮800mm, ∮1000mm. | |

| Primer coationg | Gravure Coating Method | ||

| Laminating | Press | 3 roll press type | |

| Coling roll Dia | ∮600mm | ∮750mm | |

| Sandwich winder | Turret with Auto splice | ||

| Trimming | Razor knife type | Combined Razor and ring knife type | |

| Extruder | Output | 220kg/Hr | 325kg/Hr |

| Carriage | One way | Motorized 3 way movement/td> | |

| Screw design | Single flight type | Barrier flight type | |

| DIE | Coating thickness | 12~50 mircon | |

| Deckle design | Inner Deckle type | ||

| Die opening | 600mm~1350mm | ||

| Control | Drive | Fully automatic control system with AC Vector motors | |

| HMI | Option | Standard | |

| Option | APC, Corona treater, Powder sprayer, Ozone generator | ||